Shop By Category

Related Links

Wire EDM is a popular manufacturing method in the industry. We handle Wire EDM jobs in Coquitlam and Vancouver.

What is Wire EDM?

Wire EDM (Electrical Discharge Machining) is a high-precision machining process that utilizes a thin, electrically charged wire to cut through electrically conductive materials, such as metals. In this process, the wire is continuously fed through the material, while electrical discharges between the wire and the workpiece erode the material, enabling the machine to cut complex shapes and contours with exceptional accuracy.

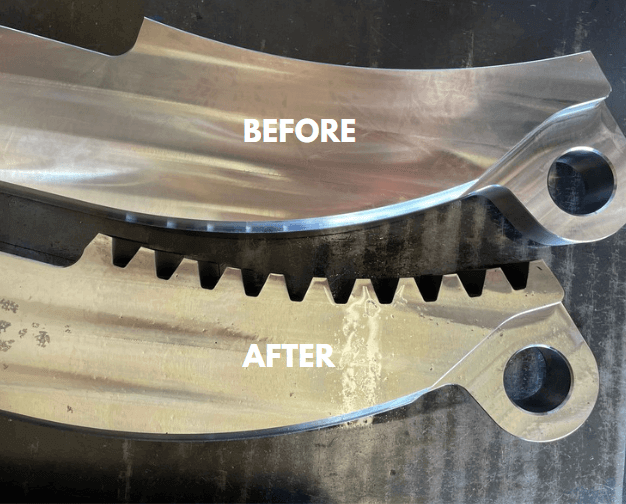

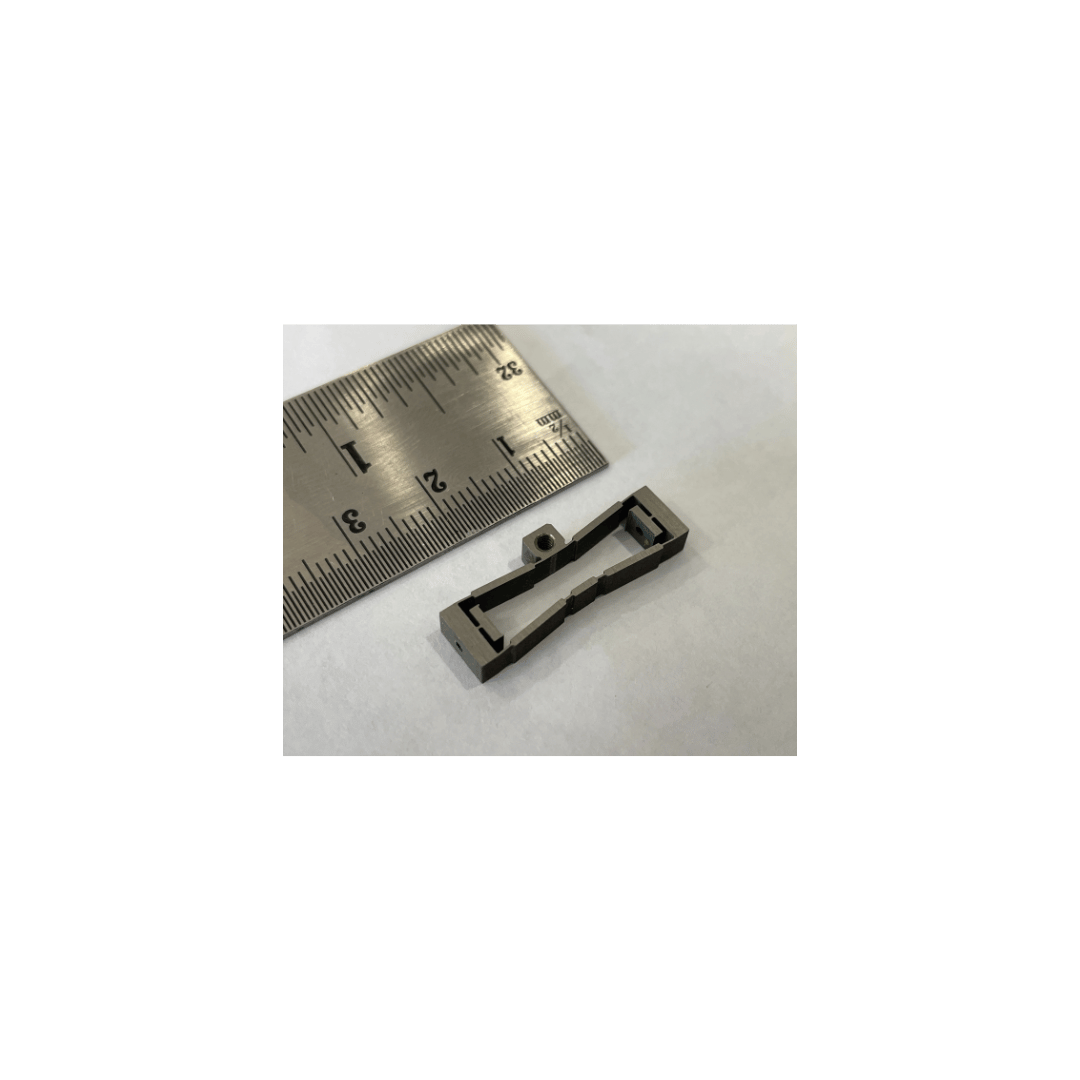

At Punch Tools, the Mitsubishi FX10K machine employs this advanced technology to achieve ultra-fine, intricate cuts. Also known as wire-cut EDM or wire erosion, this process is capable of creating precise shapes or holes in hard and conductive materials, which may be difficult to machine using traditional methods. The method works by using a thin wire electrode, which, when combined with carefully controlled electrical discharges, erodes the material in a highly controlled manner, allowing for detailed and burr-free results.

How does EDM Wire-Cutting work?

The way it works is really quite simple. An electrical discharge (spark) is created on a conductive wire, typically brass, which passes through the material, giving it a clean cut. The entire operation takes place in a submerged tank filled with dielectric fluid, which serves as a cooling system for sparks and a flushing mechanism for debris. The cut can go through the entire piece and may start from the edge or from a predetermined hole through which the wire is fed.

Punch Tools is one of the few places offering Wire EDM and Drill EDM Machining in Vancouver BC.

Watch our video below to see how we cut tough metal using wire EDM

What can an EDM Wire-Cutter do?

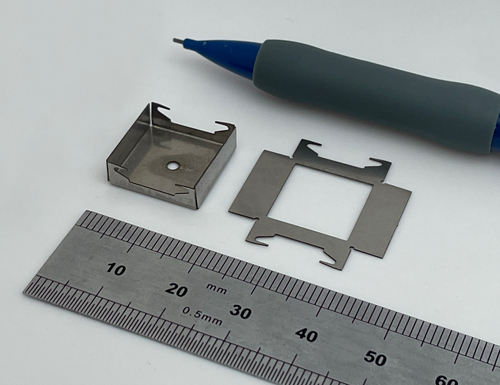

The possibilities are endless when using an EDM to extract shapes from materials, allowing us and our customers to create unique pieces for creative projects.

Complex shapes, such as the winged face below, are examples of what the Mitsubishi FX10K can achieve. A piece cut to precision.

Why use EDM Wire-Cutters?

EDM machines, such as the Mitsubishi FX10K, are the perfect for creating complex shapes that cannot be cut manually, thus eliminating the human error factor.

Wire EDM also offers an advantage when cutting through hardened tool steel. For very high tolerance applications measured under one thousandth of an inch, Wire EDM avoids distortion from heat treating after cutting.

Electrical Discharge Machining is becoming an increasingly popular manufacturing method, and more companies are adopting it. That's why we are proud to be one of the few offering Wire EDM machining solutions in Coquitlam and Vancouver.

ABOUT US

OUR SERVICES

TOOL & DIE MFG

OUR PRODUCTS

INDUSTRY LIBRARY

11-211 Schoolhouse Street

Coquitlam, BC, Canada. V3K4X9

Telephone

604-521-6444

1-800-668-4996